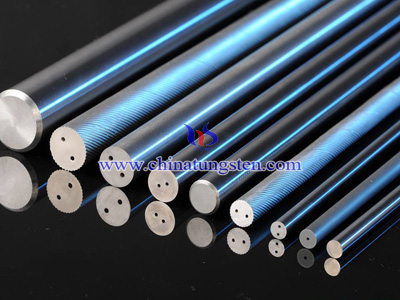

Tungsten Carbide Rod Powder Extrusion Molding

There is easily created cracking when produce tungsten carbide rods with traditional processing method, and it costs a lot. So, many tungsten carbide rod producers are try to find a more economical and qualified way. According to statistics, more than 70% of the world's rods are produced under extrusion molding process.

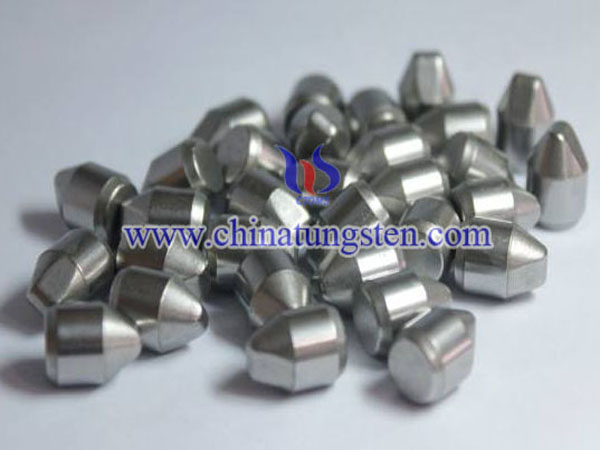

Because it can achieve large deformation under high static pressure, and has advantages technically and economically, thus extrusion technology is widely used in material processing. It can not only be used in shaping rods, tubes and wire, and also various types of composite materials. Powder extrusion molding is one of the extrusion technologies, which is having the mixture of powder and certain amounts of binders and plasticizer processed into blanks of the required shapes and specifications. It is the combination of traditional plastic molding techniques and modern powder metallurgy techniques, and it can be used in shaping unrestricted shaped pieces under the condition of low temperature and pressure.

In recent years, both in the extrusion technique and equipment, people from home and abroad achieve great progress, and the range of the those products are increasing, also in quality.

Characteristics of tungsten carbide rod powder extrusion molding: no restrictions on length, average vertical density, continuous forming rate and efficiency.

»» PDF Extended reading:

Tungsten Carbide Rod Forming Technology

New Process Study Tungsten Carbide Rod Cutting