Tungsten Carbide Rod Extrusion Process Principle

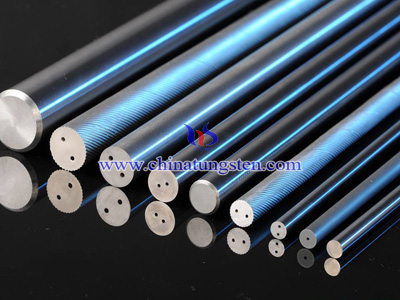

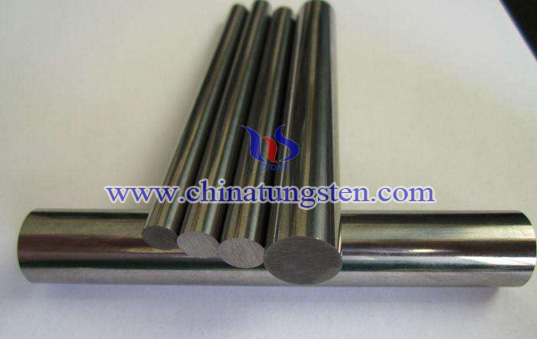

Tungsten carbide rod extrusion process is handled through the plasticized mixture into the extruder barrel, in the extrusion cylinder mold placed at one end, the mold with the desired end product extruded from die hole, the other in the extrusion barrel end into the extrusion punch, the pressure of the extruder passed through the mixture extrusion punch to make holes through the die into a certain shape of the products.

Extrusion, the extrusion material in the external force as shown in the stress state. Punch external force acting in a positive pressure to the extrudate, and molding the mixed material of the side wall of pressure, while there is extruded from the die wall and the relative movement between the material and the resulting friction. Therefore, in the extrusion process. Extruded material deformation is always two-way compression and stretching out.

»» PDF Extended reading:Impact extrusion tungsten carbide rod Quality Factors