Application of Tungsten Carbide Rod

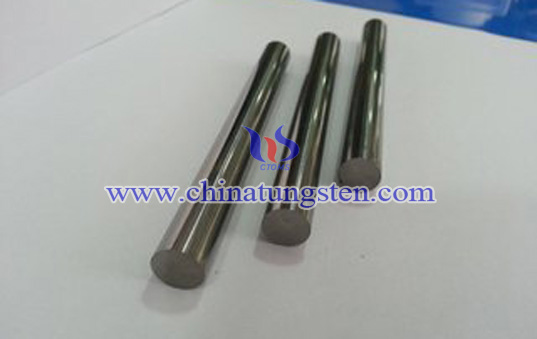

Tungsten carbide rod is mainly applied in making drills, end mills and reamers. And it is also used for cutting, punching and measuring tools. It is used in the industries of paper making, package, printing, non-ferrous metal processing. Also, it is widely used processed as HSS cutting tool, carbide end mills, carbide cutting tool, NAS Cutting tool, Aerospace cutting tool, carbide drill, milling cutter core drill, high speed steel, taperd end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, double margin drill, metal cutting saw, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter etc.

The grade of YG6, YG6X, YG8 is better wear resistant than Mk6, it can used for hard wood, processing original wood aluminum section bar, brass rod and cast iron, etc. The grade of YG10 is wear and percussion resistance, used for processing hard wood, soft wood ferrous and non-ferrous.

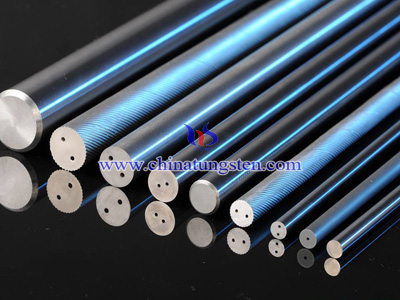

They are manufactured as standards with one, two, or three holes, straight or twisted to a 30 or 40 degree helix, or solid with no holes. Tungsten carbide rod are mostly applied for end mill and drill with sub-micron grain grade YG10X, for non-ferrous precision cutting and wood cutting with Sub-micron grain grade YG6X, and for fibre glass reinforced plastics, titanium alloys, hardened steel with Ultra-fine grain grade YG8X etc.

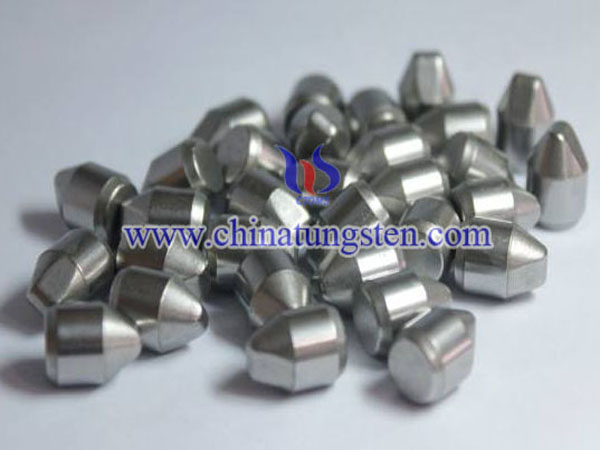

Tungsten carbide rod not only can be used as cutting and drilling tools(such as micron drills, twiste-drills, vertical mining cutter index able file)also can be used as typing needles, rollers various wear parts and structural materials. Besides, it can be extensively used in many fields, such as mechanical, chemical, petroleum, metallurgical, electronic and national defense industry.

In addition, we can provide customer with accurate appearance, size, and you can choose any tungsten carbide grade as you like. If you have any interest in tungsten carbide rod, please feel free to contact us.