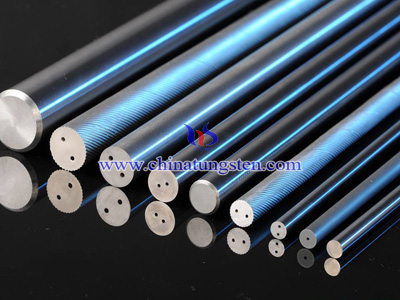

Tungsten Carbide Rod Forming Molding Process

Tungsten carbide rod forming molding process can be divided into two pression methods, which is horizontal direction and vertical direction.

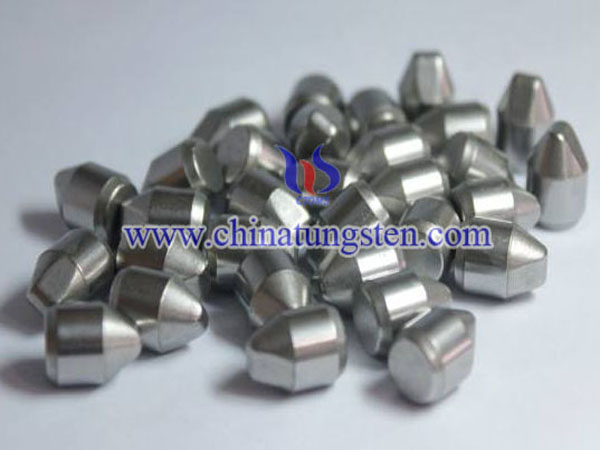

Firstly, shape the two punches of the mold into a round-rod shape and press out powder between them. The length of rods made from this process would be easily restricted of the specifications by the mold and pressing machines. Due to the inaverage pressure of the powder pellets from both punches, gaps can be noticed at the blank voids, and they are difficult to close. There's some possibilities that the cobalt contents are increasing and thus creates the so-called cracking.

Similar to the horizontal repression process. It's characterized in that those finished rods are restricted by the pressing machine and cannot be easily extruded out in the vertical direction.

Use porous molds in the bulk molding(for the manufacture of drills and end mills), with the diameters between 5 ~ 25mm, and the maximum can be up to 38mm and the production of rods of length of 105mm can yield up to 10~15t/month.

»» PDF Extended reading: Tungsten Carbide Rod Forming Technology