Ultra-fine Tungsten Carbide Rod Extruded Agent Effect

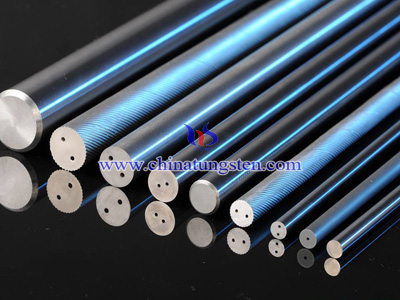

Using the average particle diameter of 0.6 ~ 0.8μm WC powder(Adding a certain percentage of the VC and Cr3C2As grain growth inhibitors),The average particle blame for the 0.9μm Co powder, obtained after wet milling WC-10% Co cemented carbide mixture. Has been evaporated and then add the prepared carbide rod extrusion forming agent by mixing obtained after feeding. Feeding the ram extruder extruded into billets. Billets by solvent degreasing, thermal degreasing, and after a certain sintering sintering, pressure treated, prepared Φ6.1 mm, Φ7.1 mm, Φ8.1 mm and other specifications of ultra-fine grain tungsten carbide rod finished product.

The Φ8.1 mm Specifications bar warp cutting, grinding obtained after GB-A bending specimens, testing their physical and mechanical performance, data compression tungsten carbide rod see the physical and mechanical properties of the table. Sample microstructure photograph shown below.

| Sample No | Density/(g/cm³) | Hardness(HRA) | Flexural strength/MPa | Coercive forceHc/(KA/m) | Cobalt magnetic values Com/% |

| 1 | 14.4 | 92.0 | 3870 | 19.3 | 9.42 |

| 2 | 3720 | ||||

| 3 | 3970 | ||||

| 4 | 4180 | ||||

| 5 | 3960 |

Bending-polished specimen microstructure Bending specimen microstructure corrosion state

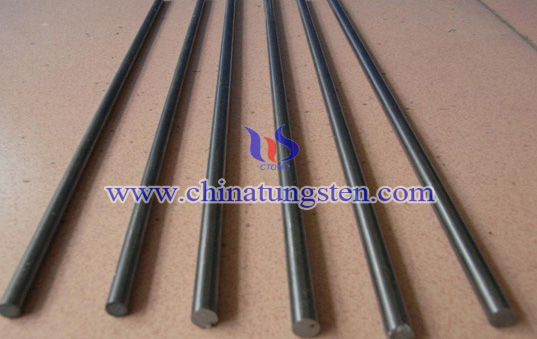

By cold isostatic pressing process to produce the same grade, the same size ultra-fine grain tungsten carbide rod, and its mechanical and physical properties data, see cold isostatic pressing physical and mechanical properties of the bar table.

| Sample No | Density/(g/cm³) | Hardness(HRA) | Flexural strength/MPa | Coercive force Hc/(KA/m) | Cobalt magnetic values Com/% |

| 1 | 14.39 | 92.0 | 3850 | 19.8 | 9.90 |

| 2 | 3770 | ||||

| 3 | 3700 | ||||

| 4 | 4210 | ||||

| 5 | 3920 |

These test results show that the use of new ultra-fine tungsten carbide rod extrusion agent prepared ultra-fine grain tungsten carbide rod, microstructure no obvious defects, uniform and fine grain size, hardness and flexural strength can be achieved simultaneously high level.

The two bars for drilling test, test parameters and results of test parameters and see the results of the drilling tool table. Combined with small quantities to provide the user after the trial proved that the performance bar by cold isostatic pressing process to produce ultra-fine tungsten carbide rod performance considerably.

| Props No | Cutting speed v/ ( m/min ) |

Feed ƒ/ ( mm/r) |

Cutting depth αp/mm |

Number of holes (a) |

Remark |

| 1 | 67 | 0.15 | 36 | 3020 | Extruded bar stock |

| 2 | 2987 | Extruded bar stock | |||

| 3 | 3108 | Cold isostatic bar | |||

| 4 | 3035 | Cold isostatic bar |

Note: Tool model 78-270250005/2; workpiece material for HT.

»» PDF Extended reading: Ultra-fine tungsten carbide rod extruded agent design