Extrusion dies

The extrusion process, the powder mixture, there is the problem of forming and densification. If the mold designed properly, will produce extrusion density is too low and uneven phenomenon, which causes subsequent sintering deformation. So tungsten carbide rod extrusion production process, many factors affect the quality bar.

As long as a reasonable step to determine the process parameters, strict control of degreasing process carbon - hydrogen equilibrium, the sintering process of carbon - oxygen balance, extrusion quality tungsten carbide rods can be effectively protected.

In the design of extrusion dies, it must be properly selected compression ratio.

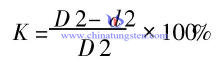

Compression ratio is calculated

Where: K is the compression ratio, D, d respectively, the outer diameter of the mouth and squeeze squeeze the inner diameter of the mouth.

Compression is generally controlled K ≥ 95%, extrusion nozzle taper angle control at 45 ° ~ 75 °, the taper angle is too small, although easy to flow into the feed belt shape, but the rough center density will be reduced accordingly; taper angle is too large, the extrusion pressure is too large, will lead to rough horizontal stratification.

»» PDF Extended reading:Impact extrusion tungsten carbide rods Quality Factors

If you have any other question or inquiry of tungsten carbide rod, please feel free to contact us through the following methods:

Emails: sales@chinatungsten.com

sales@chinatungsten.com

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

More Info>>

Tungsten Carbide rods

Tungsten Carbide Products

Inquiry | Feedback | Suggestion | Comment