Carbon

In the production of tungsten carbide, cemented carbide carbon content plays a vital performance of the product or even decisive role.

Normal tissue tungsten carbide of WC and Co two phases, a third phase of the alloys appeared to have an adverse effect, so the control of the carbon content in the alloy is a critical issue.Alloy carburizing and decarbonization will cause performance degradation,Decarburization phase generated η phase(W3Co3C), η phase is generated in part compounds Co, decrease in the strength of the alloy, in addition to three yuan η phase is a brittle carbide compound, properties of the alloy greatly; carburization, the excess carbon in the form of free carbon, reducing the alloy density, the compactness of the material damage, its strength, hardness.

First,Debinding and burn the carbon content is controlled during

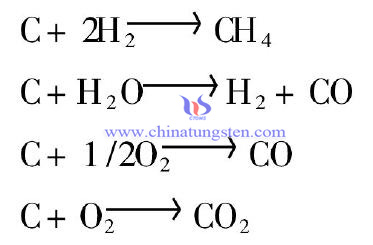

Conventional degreasing tungsten carbide preform extrusion molding method for the hot degreasing, Co binder phase due to oxidation, so skim generally carried in a protective atmosphere. For hot degreasing, on the one hand due to join a large binder, this binder, mostly organic, produce a certain amount after pyrolysis carbon residue; hand, skimmed process due to the carbon blanks with feedstock oxygen, degreasing atmosphere of hydrogen, water vapor reaction products may cause removal, the reaction is as follows:

Carbon content in the skim process control is mainly controlled atmosphere composition and improved degreasing degreasing process parameters. Reasonable set of skimmed heating curve, temperature and other process parameters and control the composition of the atmosphere and the dew point skimmed, skimmed billet rods for ensuring quality and control of carbon has a very important significance.

Second, the carbon content is controlled vacuum sintering

The carbon content is controlled vacuum sintered in vacuum sintering is carbon - oxygen balance control, vacuum sintering decarburizing duality carburization, the low temperature stage of the decarburization stage carburizing orientation and inclination.

tungsten carbide material in the wet mixture, drying and sieving, the gathered a large amount of oxygen (usually in the form of an oxide), vacuum sintering, the oxide products mainly by the removal of the free carbon and a compound in WC to the reduction of carbon, the reaction is as follows:

MeO + C - Me+CO↑

MeO + 2C - MeC+CO↑

Mixture of high oxygen content of the alloy produced in a vacuum sintering has a strong tendency to decarburization. So the vacuum sintering carbide, mixed compound of carbon, oxygen levels must be strictly controlled.

Vacuum sintering the carbon content is controlled, the main measures of strict control of mixture of carbon and oxygen content, to stabilize at a certain range of fluctuation; strictly control the amount of fat in the process of changes in the carbon. To precisely control the carbon content, the first to accurately draw Mixture aerobics, degreasing and sintering process may produce oxygen decarbonization, and thus introduced the total carbon loss each step, resulting in the blending process with appropriate carbon.

»» PDF Extended reading:Impact extrusion tungsten carbide rods Quality Factors

If you have any other question or inquiry of tungsten carbide rod, please feel free to contact us through the following methods:

Emails: sales@chinatungsten.com

sales@chinatungsten.com

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

More Info>>

Tungsten Carbide rods

Tungsten Carbide Products

Inquiry | Feedback | Suggestion | Comment